POLYGONAL TILES

NATURAL STONES FOR TERRACE, GARDEN, PATHS, AND WALLS

Nice to have you here. Be warmly greeted and welcome to our informative page about Polygonal Slabs. My name is Roy Preuß, I am the managing director of the online shop bruchsteinplatten.de which is located in the logistically perfect home of SL Schwedt Logistik GmbH in Gewerbepark-Meyenburg 1 in Schwedt.

Together with my team, we offer Polygonal Slabs with passion first-hand.

Current customer feedback

What are polygonal slabs?

The very technically sounding word Polygonal plate The beautiful, vibrant Mediterranean optical effect is in no way justified. The word "polygon" comes from ancient Greek and translates to "Vieleck" so a geometric shape with many corners. In the case of the Polygonal plates precisely irregular or asymmetrically shaped polygonal slabs made of natural stoneIrregular means here that all the rubble stone slabs have an individual shape, making each one unique and thus having different or irregular edges and many corners, varying sizes and surfaces. It is truly a natural product through and through.

Polygonal slabs offer through their natural irregularity not only a unique appearance, but also versatile applications in Outdoor and Indoor Area. Whether as flooring for Terraces, Paths, or as a decorative element on Facades and walls – the versatility of polygonal slabs leaves little to be desired. Their rough surface also ensures slip resistance and safe walkability, making them particularly attractive for outdoor areas. Due to the variety of available natural stones such as Grauwacke, Porphyr, Quartzite or Slate Polygonal slabs can be perfectly adapted to the respective environment, thus contributing to the creation of a harmonious overall impression.

Polygonal natural stone slabs for your project

Patio slabs made from various types of natural stone, such as quartzite natural stone, slate, or greywacke are valued for their special appearance and high durability. Patio slabs made of polygonal broken stones not only look natural, they are natural. In this category, we only offer patio slabs that are frost-resistant, slip-resistant, and not too thin.

Our focus is exclusively on high-quality polygonal slabs for your patio made of natural stones such as quartzite, slate, and greywacke.

Support and advice: Mon - Fri from 8 am - 4 pm by our sales representatives. Phone: +49 (0) 3332 26 70 78 27 or via email at: verkauf@bruchsteinplatten.de

-

Quartzite Polygonal Slabs Clara

Vendor:bruchsteinplatten.de5.0 / 5.0

(1) 1 total reviews

Regular price From €465,00 EURRegular priceUnit price €74,50/m²€930,00 EURSale price From €465,00 EURSale -

Polygonal slabs Slate Negra

Vendor:bruchsteinplatten.de5.0 / 5.0

(1) 1 total reviews

Regular price From €445,00 EURRegular priceUnit price €89,00/m²€890,00 EURSale price From €445,00 EURSale -

Quartzite Deep Sea polygonal slabs

Vendor:bruchsteinplatten.deRegular price From €455,00 EURRegular priceUnit price €91,00/m²€910,00 EURSale price From €455,00 EURSale -

Natural slate Scabra facade stone 1-3 cm

Vendor:bruchsteinplatten.de5.0 / 5.0

(2) 2 total reviews

Regular price From €435,00 EURRegular priceUnit price €87,00/m²€870,00 EURSale price From €435,00 EURSale -

Quartzite broken stone slabs Auralis

Vendor:bruchsteinplatten.deRegular price From €545,00 EURRegular priceUnit price €109,00/m²€1.090,00 EURSale price From €545,00 EURSale -

Quartzite broken stone slabs Antares

Vendor:bruchsteinplatten.de5.0 / 5.0

(1) 1 total reviews

Regular price From €545,00 EURRegular priceUnit price €109,00/m²€1.090,00 EURSale price From €545,00 EURSale

Enjoy a splash of color with colored quartz gravel joints between your polygonal slabs

Aside from the shape, polygonal slabs or natural stone patio slabs are also individually characterized by color, grain, and surface, emphasizing the lively and natural southern flair.

In principle, broken slabs are laid like a mosaic, and the resulting gaps (joints) are also irregularly grouted. This emphasizes the intentionally loose character and creates an authentic and harmonious interplay.

By the way, my wife inspired me to more color joy and individuality when it comes to joints and mortar. You can now also enjoy the result. Our self-developed colored joint mortar is available in 14 different colors. This way, you can let your creativity run wild in the design of your patio or pool landscape or garden and indulge in colorful installation.

Polygonal slabs are intended for what purpose, where do you use the stones, or what do you do with polygonal natural stone slabs?

Of course, your imagination knows no bounds and you can implement any projects that come to mind. Here are the most common applications for polygonal slabs made of natural stone, and I will also show you some examples for your inspiration. Not all materials are suitable for every purpose, as there are different strengths and properties. For example, areas that are driven on by vehicles require stronger stones and a suitable substructure to prevent your polygonal slabs from breaking under the load later on.

I cordially invite you to contact our specialist advisory team for your specific project from Monday to Friday between 8 am and 4 pm at +49 (0) 3332 26 70 78 27. Here you can ask all your questions. Outside of our business hours, feel free to use our contact form.

Customer photos of polygonal slab projects such as terraces, house entrances, and house facades

Here are examples of what polygonal slabs can be used for

There are countless possibilities and applications, your imagination knows no bounds. Polygonal slabs are suitable in the garden, as terrace, edging, paths such as garden paths or stepping stones. As flooring, edging for pool, swimming pool or pond. For your barbecue area, as seating areas, garage driveway, cladding such as cladding stones for walls and fences, as rustic wall cladding indoors and outdoors. But of course also as a balcony and entrance to the house, just to name a few examples.

Depending on how the sun or the moon shines, the various surfaces unfold their characteristics depending on the time of day or night. Magic through gentle grains, bright lines, and dark inclusions. The diversity of the various Quartzite rubble stones It is always impressive when quartz veins and crystals shimmer in the light and fine striations become visible.

Before I list the world of polygonal slabs for the sake of completeness, I would like to briefly explain why we primarily focus on the outdoor area and why certain types of polygonal slabs are not suitable for this purpose. If you want to do something particularly well, you need to focus. This has the advantage that you can Specialist in polygonal slabs for outdoor use will and on the other hand can pass on the shopping benefits to its customers.

Natural stone slabs made of sandstone and marble are not frost-resistant and are at great risk of breaking in frost, which limits their use as Garden slabs, Terrassenplatten or plates for Sidewalks In Germany excludes. Limestone reacts sensitively to acids and salts and is therefore also unsuitable for outdoor use*.

What natural stone are polygonal slabs made of?

These natural stone types of polygonal slabs are available (sorted by hardness):

Granit, Grauwacke, Quartzite, Porphyr, SlateBasalt, gneiss, marble*, limestone* and sandstone.

Polygonal slabs made of natural stone are a popular alternative to tiled surfaces and are used both indoors and outdoors. They are more durable than tiled surfaces, as they are less prone to damage and easier to clean. In addition, they are easy to install and create a harmonious atmosphere.

Visit our polygonal slabs and more exhibition in Schwedt

If you would like to get a personal impression, you are welcome to visit our exhibition at Gewerbepark Meyenburg 1 in 16303 Schwedt. There we will be happy to show you all materials in person and answer all your questions on site.

The world of natural stones is colorful: polygonal slabs with great surfaces

-

Kallisto Quartzite Polygonal Slab

View Kallisto QuartziteKallisto is a quartzite slab suitable for garden paths, driveways, facade cladding, pool edging, pedestal cladding, pond edging, wall cladding, balconies, pavements, and as terrace slabs.

-

Black Slate Polygonal Plate

More about Negra SlateThe noble Schieferplatten Negra are best suited for outdoor use. Whether as a patio tile, as a walkway stone, or to adorn the fish pond, the Schiefer-Platte Negra leaves nothing to be desired in its versatility of use.

-

Antigua Slate Polygonal Plate

Antigua SlateThe Slate Antigua is a particularly characterful natural stone. It radiates in a color spectrum that ranges from rusty red tones to earthy brown and stylish gold. This makes the slabs look antique and nostalgic - as if from a bygone era.

Color and texture variety of polygonal slabs

Our personal favorite natural stone Quarzit impresses with its variety of colors and structures ranging from Mediterranean tones, light colors to nostalgic or strong and earthy dark tones. Interlaced with inclusions such as quartz veins and quartz crystals, Quarzit offers an impressive quartz glitter effect. Depending on the desired color effect of the broken stones, you can either emphasize the natural effect or deepen the colors with an impregnation.

These are the colors offered by the different Quarzit stones:

-

-

GRAUWACKE

More about GreywackePolygonal plate, fiery red tones, earthy brown, and rusty metallic gray tones.

-

QUARTZITE LEMURIA LIGHT

to Lemuria Light QuartzitePolygonal slabs in fieldstone look with quartz gloss, bronze, brown, and shimmering.

-

QUARTZITE DEEP SEA

Deep Sea Quartzite InfoPolygonal slabs, dark blue and anthracite with few lighter inclusions, quartz crystals and quartz veins.

-

QUARTZITE COPPER

to Copper QuartzitePolygonal plate, silvery shiny, transitioning from cream to brown.

-

Our absolute favorite natural stones: Polygonal slabs made of quartzite

We love quartzite and there are many good reasons for that. Quartzite is more resistant than granite, totally insensitive to impurities such as dirt and stains, robust, easy to care for, and durable. The abrasion resistance of quartzite is unparalleled, as is its weather and frost resistance. There are quartzite broken stones in thicknesses ranging from 2 to 5 cm with hardness levels of 6 to 7. This wonderful natural stone absorbs very little water, is characterized by its Mediterranean color scheme, and is the only stone with the so-called quartz glimmer effect - a real plus that always attracts attention.

bruchsteinplatten.de

Terrace package COMPRESA Plana - easily configure yourself

Sharing makes you happy

And here you have the selection and description of 10 types of quartzite polygonal slabs at a glance

Antares polygonal slabs

Antares - relatively smooth natural surface in pink, accents with reddish brown tones

Auralis Polygonal Plates

Auralis - relatively smooth natural surface in yellowish tones

Jasmares polygonal plates

Jasmares - relatively smooth natural surface in greenish gray

Polygonal plates Polaris

Polaris - relatively smooth natural surface in shades of white and light gray

Polygonal plates Copper

Copper - Shades in gray silver shimmering and cream tones; occasionally warm brown tones; unobtrusive, natural; modern ambiance; exclusive; high quality

Lemuria Light Polygonal Plates

Lemuria Light - Soft red tones, strong, earthy brown; occasional inclusions of metallic gray; boundless variety of facets; fine, light lines, dark inclusions; antique charm

Kallisto polygonal plates

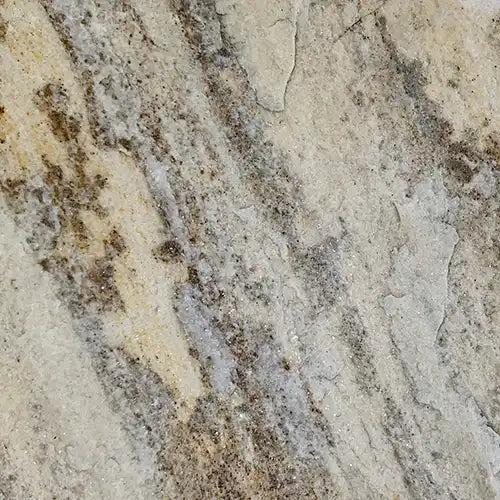

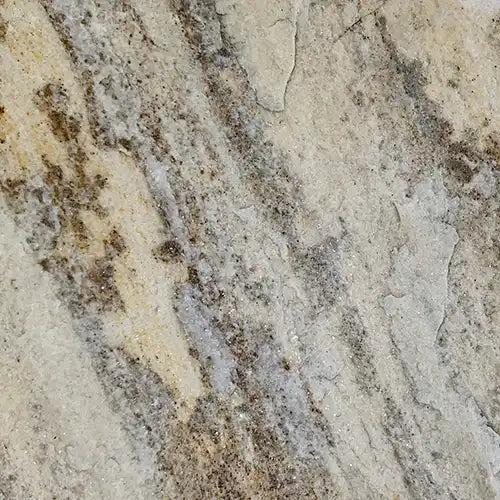

Kallisto - unique color play; Mediterranean look; creamy, gentle yellow tones; strong earthy brown; rustic; traditional; modern and luxurious; shimmer enchantingly in sunlight

Polygonal plates Deep Sea

Deep Sea - elegant, dark, calming anthracite; few lighter inclusions such as quartz veins or quartz crystals; the slabs look as if they come straight from the depths of the sea

Polygonal plates Violet

Violet - warm, sandy yellow, beige, and brown tones; makes the sun rise; holiday mood; noble; when light falls on the slabs, they shimmer in a soft violet

Clara polygonal slabs

Clara - expressive beige color tone; classic style; interspersed with fine darker inclusions. Highest quality; graceful elegance; exclusive ambiance

LAYING POLYGONAL SLABS IS NOT SO DIFFICULT

How are polygonal slabs laid?

The laying of polygonal slabs is done on a flat surface after the subsoil has been prepared. Irregularities should be repaired and the subsoil cleaned before laying the slabs. The polygonal slabs are arranged in a pattern and grouted with grout. It is recommended to maintain a joint width of at least 10 mm. After all slabs have been laid, the floor can be sealed with a natural stone impregnation to extend its lifespan. For the laying of polygonal slabs, we have developed special terrace packages COMPRESA that include both the slabs and the grout, quartz gravel, and the impregnation.

So you prevent cement haze and at the same time relieve the environment

There are numerous instructions on the internet for laying polygonal slabs, which, with few exceptions, are based on a cement or concrete base. This is not environmentally friendly due to the necessary sealing and ultimately complicated, as a corresponding slope and drainage must be created. The well-known problem of cement haze then has a negative impact on the beautiful and desired appearance of the polygonal slabs. The cracking of the concrete slab over time causes further difficulties. For this reason, we have developed a solution that is practical and optimized to relieve our environment. Furthermore, it makes cement haze and cracking impossible because we do not use cement or concrete. Our cement-free installation method with quartz gravel and resin is water-permeable and directs water through the joints over the quartz gravel layer directly into the soil. A sensible, simple, and environmentally friendly solution that does not require sealing.

Which substructure for polygonal slabs?

The foundation here is the so-called concrete recycling, which essentially consists of granular concrete rubble and should have a height of at least 15 cm in the previous excavation. We have chosen this base layer in combination with quartz gravel for its excellent compaction ability and water permeability. For those who like to do DIY projects, we have created a Do-it-yourself (DIY) guide.

If you prefer to hire a specialist company

Within the new federal states, we are able to professionally install your polygonal slabs starting from 100 m² upon request by a trained in-house installation employee. This way, you have everything ready from a single source. Outside the new federal states, we have the following recommendations for you.

NATURAL STONES POLYGONAL - EASY GROUTING MADE SIMPLE

It's a bit like baking a cake. You just need the right ingredients and a recipe. You mix a "dough", pour it into the "mold", and smooth it out. Except here, you don't need an oven but 24 hours in the fresh air. Then sweep away any remaining debris. Done! Sounds simple, and it is.

And here is the ingredient list for 4 m²

• 25 kg Colorquarz / Grout

• 1 kg Resin

• 1 mixer

• 1 mortar bucket

• 1 smoothing trowel

• 1 hand broom with stiff bristles

• 1 broom

How to grout polygonal slabs?

DIY guide to laying polygonal slabs: The "recipe" for grouting rubble stones

1. Mix Colorquarz and Resin with the mixer in the mortar bucket until all grains have a uniform shine and a homogeneous "rolling" mass forms

2. Pour the mass onto the laid natural stone slabs

3. Spread the mass on the surface with the smoothing trowel, which then "rolls" into the joints

4. Sweep away any remaining grains with the hand broom

5. Let it rest for 24 hours

6. Sweep away any remaining residue with the broom.

Done!

VIDEO TUTORIAL FOR GROUTING POLYGONAL TILES IN JUST 6 MINUTES

FAQ - Answers to frequently asked questions about polygonal slabs

What are polygonal slabs and what are they used for?

Polygonal slabs are natural stones that are cut in various sizes and shapes. They are often used as flooring in outdoor areas, such as on terraces or walkways.

What are the different types of polygonal slabs?

There are different types of polygonal slabs, such as sandstone, basalt, slate, quartzite, graywacke. Each stone has its own colors, nuances, and surfaces.

Which substructure is suitable for laying polygonal slabs?

Polygonal slabs are laid on a suitable surface such as quartz gravel, concrete, or sand. The installation is done by placing the stones with uniform spacing for the joint and a desired laying pattern.

How can I clean and maintain polygonal slabs?

To clean polygonal slabs, we recommend using mild cleaning agents and promptly removing stains. Regular maintenance such as sweeping leaves and dirt also helps to maintain the appearance of the slabs.

How do I determine the right size and thickness of the polygonal slabs for my project?

The size and thickness of the polygonal slabs depend on your project. We are happy to help you calculate the required quantity and size. Phone: +49 (0) 3332 26 70 78 27 or by email at: verkauf@bruchsteinplatten.de

What colors and patterns are available for polygonal slabs?

We offer various polygonal slabs made of quartzite, slate, or greywacke. Depending on the stone, the surfaces, structures, and colors differ, such as gray, beige, red, brown, yellowish, etc. Each stone has unique "patterns" and structures.

How long do polygonal slabs last and are they durable?

How do I prevent my polygonal slabs from slipping?

How do I calculate the required quantity of polygonal slabs for my project?

Basically, you measure the square meters of the area you want to cover. Depending on the type of stone and the size of the slabs, we recommend ordering a 10% surplus. We are happy to help you calculate the required amount of polygonal slabs for your project.

Support and Advice

Mon - Fri from 8 am to 4 pm by our landscaping professionals and customer advisors.

Phone: +49 (0) 3332 26 70 78 27

or by email at: verkauf@bruchsteinplatten.de

What are the advantages of polygonal slabs compared to other floor coverings?

A major advantage of polygonal slabs is their natural beauty and durability. Compared to other types of flooring, they are often more affordable and easier to install.

Which joint mortar is the best for polygonal slabs?

For grouting polygonal slabs, we recommend a grout based on synthetic resin. This grout is particularly water-permeable and resistant to weather influences and mechanical stress. Our grout can be matched to the color of the polygonal slabs to achieve a harmonious overall appearance. When choosing the grout, make sure it is suitable for outdoor use.

Can I use rock salt on polygonal slabs in winter?

It is not recommended to use rock salt on polygonal slabs, as salt can attack and damage the surface of the slabs. The chemicals in salt can also penetrate the stone and cause long-term damage. Instead, you should use alternative methods for snow removal and ice control, such as shoveling snow or spreading sand or gravel. However, if you are forced to use rock salt, make sure that the polygonal slabs are properly sealed and that the salt is removed immediately after the snow has melted.

Are polygonal slabs drivable?

Polygonal slabs are generally suitable for pedestrian traffic and light vehicles such as bicycles or scooters. However, for use on drivable surfaces such as driveways or parking lots, special, thicker, and more resistant stones are better suited. If you want to ensure that your polygonal slabs are drivable, you should seek expert advice from a stonemason or a landscaper to ensure that you are using the right stones and laying techniques. We have extra massive stone slabs in our range for this purpose.