Collection: Resin

The impressive versatility of resin

Resin is a plastic material consisting of two components, a resin and a hardener. Resin is a powerful material that is very resistant, chemically resistant, and durable. It can be used in a variety of applications, including as a coating, adhesive, sealant, and filler for laying natural stone slabs. Resin can also be used as a durable replacement for other materials such as metal, wood, and plaster. It is also a very resistant material that is well suited for use in extreme environments, such as outdoors or in refrigerated rooms. Resin can be easily processed, shaped, and color-stable, making it a versatile choice for countless applications.

Support and advice

Mon - Fri from 8 am - 4 pm by our customer advisors. Phone: +49 (0) 3332 26 70 78 27 or by email at: verkauf@bruchsteinplatten.de

Epoxy resin - A robust solution for many applications

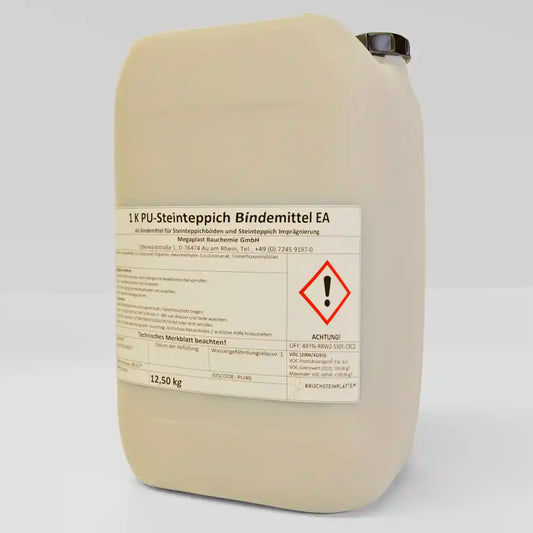

At bruchsteinplatten.de, we use resin and special quartz gravel for laying and grouting polygonal natural stone slabs. Our resin, a ready-to-use 1K (component) solution, is a very strong, extremely resistant resin adhesive specially developed for use in laying natural stone slabs. It is used for bonding and solidifying decorative gravel and natural stone chippings. The adhesive is easy to work with, allowing for quick and easy installation. It provides excellent grip and protects the natural stone slabs from water, dirt, and moisture. Our resin is a ready-made resin mixture for gravel sizes ranging from 0.7 to 6 mm, no resin and hardener need to be mixed. For an area of 1 m² with a build-up height of 3 cm using quartz gravel with a grain size of 2-4 mm, only 1.2 kg of resin is needed. The properties are solvent-free, water-resistant, odorless, easy to clean, frost-resistant (after complete curing) - or resistant to de-icing salt, and transparent.

Examples of applications of resin

Our synthetic resin is durable and suitable for solidifying washed, dry to maximum slightly damp and dust-free decorative pebbles and premium chippings of all grain sizes up to 36 mm.

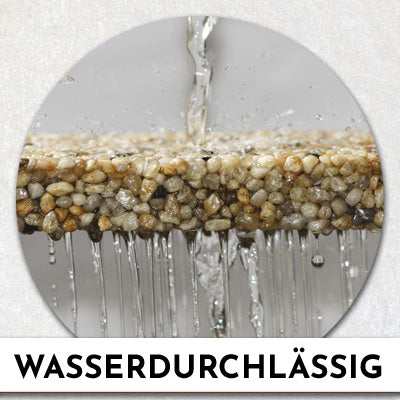

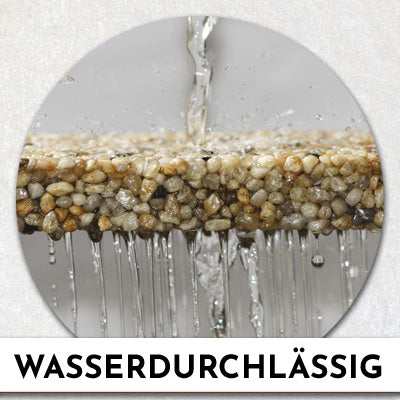

- For the production of bound, water-permeable layers

- Suitable for light and white rock types

- For decorative garden design

- Pond edging

- House edging

- Suitable for glass chippings

- Colorquarz

- Premium chippings

- Natural stone grains

- Tree edging

- Garden / front yard

- Garden paths

-

Binding agent for laying and grouting natural stone slabs

Vendor:bruchsteinplatten.deRegular price €499,00 EURRegular priceUnit price €39,92/kg

Resin and colored quartz gravel - a great team

When grouting natural stone slabs, using concrete would create a style break. By using colored quartz gravel, nature is brought into play, it becomes an optical highlight, and standing water is a thing of the past as it simply flows through the quartz gravel. The synthetic resin "adhesive" is easy to work with and provides excellent adhesion. It is also highly resistant to water and dirt, allowing for easy installation. Water permeability is crucial to avoid mold and stains. Our synthetic resin is suitable for gravel sizes ranging from 0.7 to 6 mm. For an area of 1 m² with a build-up height of 3 cm using 2-4 mm quartz gravel, only 1.2 kg of synthetic resin mixture is needed.

Here are the synthetic resin properties at a glance:

- solvent-free synthetic resin mortar

- cement-free joints

- water-resistant

- frost-resistant after complete curing

- resistant to de-icing salt

- low odor

- solidifies almost any gravel or grit

- offers countless decorative design options

- good grain-to-grain bonding

- and is VOC-free

VOC-free means that a product does not contain volatile organic compounds (VOCs). VOCs are often used as solvents in paints, varnishes, and cleaning agents and can be harmful to health. Therefore, it is important to use products that are VOC-free.

Resin and quartz gravel as jointing compound or jointing mortar

Resin is a special resin made up of various chemical compounds that help it form a very strong and durable bond. It is commonly used as an adhesive to bond different materials together. Resin is also a very common material for repairing metals, plastics, and other materials. Joint mortar is a special bonding material used for jointing and connecting building materials. It is a bonding mixture usually made up of sand, cement, and other components that help make the joints strong, firm, and long-lasting. Joint mortar is typically used for connecting bricks, stones, concrete, metals, and other materials.

FAQ - Answers to frequently asked questions about topics such as synthetic resin, epoxy resin, casting resin, and epoxy mortar

What is epoxy resin or synthetic resin?

Epoxy resin (synthetic resin) is a synthetic resin made from epoxy compounds, monomers, and fillers. It is generally considered one of the most versatile and durable forms of resin, known for its excellent chemical, thermal, and mechanical resistance. It is used in a variety of applications, including the production of claddings, repairs, coatings, adhesives, and sealants. At bruchsteinplatten.de, we use synthetic resin in combination with quartz gravel as a concrete-free, water-permeable, and frost-resistant grout.

What is epoxy resin / synthetic resin used for?

Epoxy resin is used in many areas, including the construction industry, electronics industry, automotive industry, and consumer goods industry. It is also commonly used as a primer, paint, adhesive, and sealant, as well as in art and model making. Epoxy resin is used for the production of laminates, glass, vessels, and containers. At bruchsteinplatten.de, we use resin for the substructure (screed) and for optimal laying and grouting of polygonal slabs.

With what or how do I mix or stir epoxy resin or synthetic resin?

To mix epoxy resin or synthetic resin, a stirring device or an electric drill with a stirring whisk is used. The stirring whisk must be designed to completely disperse and mix the synthetic resin. For optimal results, the stirring whisk should be made of plastic or stainless steel, as these materials do not react with the resin.

What are the advantages of synthetic resin / epoxy resin?

Epoxy resin is a very versatile material that offers many advantages. It is excellent in water and chemical resistance, heat resistance, durability, and resistance to mechanical stress. It is also easy to process and therefore ideal for the production of plastic items such as furniture, tanks, containers, pipes, and more. It is also extremely cost-effective, as it is not only durable but also easy and inexpensive to produce. It can also be manufactured in a variety of colors to meet any design requirements. Resin gives us at bruchsteinplatten.de the opportunity to ensure our customers a cement-free installation of natural stone slabs as terrace flooring in connection with our pre-treated special quartz gravel. This has the advantage that there can be no cement efflorescence or frost damage.

When is synthetic resin / epoxy resin fully cured?

Epoxy resin or synthetic resin is usually completely cured after 24 hours at a constant temperature of 15 degrees Celsius. The higher the temperature, the faster the curing process. At temperatures lower than 15 degrees Celsius, it can take up to 48 hours. We are happy to advise you on this from Mon - Fri from 8 am - 4 pm at telephone: +49 (0) 3332 26 70 78 27

How much epoxy resin or synthetic resin is needed per square meter?

It depends on the type of resin and the thickness of the layer you want to apply. Typically, you will need about 1.5 to 2 kg of epoxy resin per square meter. For an area of 1 m² with a build-up height of 3 cm using quartz gravel 2-4 mm grain size, only 1.2 kg of resin is needed.

How can air bubbles be removed from the resin?

There are various ways to remove air bubbles from resin. One way is to slowly and gently stir the mixture to release air bubbles from the resin. Another way is to treat it with a vacuum to remove the air bubbles from the resin. A third way is to dip a small brush or cotton swab into the resin and then slowly move it over the surface of the resin to bring the bubbles to the surface.

What should I mix epoxy resin / synthetic resin in?

Epoxy resin or synthetic resin should be mixed in an environment that is clean, dry, and dust-free. It is best to use a black construction bucket, also known as a mortar bucket. We recommend using protective gloves and safety goggles. For stirring, we recommend a mortar mixer, a compact 1-speed machine for mixing viscous materials with speed control electronics to adjust to the respective mixture.

We are happy to advise you from Monday to Friday from 8 am to 4 pm at telephone: +49 (0) 3332 26 70 78 27

What are synthetic resin / epoxy resin mortars used for?

Epoxy mortar is used to secure critical parts on machines and equipment. It is also useful for repairing leaks in tanks, containers, and pipes. Epoxy mortar is particularly useful when it comes to sealing liquids and chemicals that should not mix with other materials. Because it is extremely resistant to chemicals and cold, it is also a popular choice for use in refrigeration systems and storage containers. At bruchsteinplatten.de, we use it to grout and lay Polygonal slabs, natural stone slabs or broken stone slabs in a water-permeable, concrete-free, frost-proof, and durable manner.

Is epoxy or synthetic resin mortar better than cement mortar?

It depends on the requirements you have for the mortar. For very durable applications where high resistance to chemical substances and moisture is required, resin mortar is usually the best choice.

CONCRETE-FREE, WATER-PERMEABLE, AND FROST-RESISTANT NATURAL STONE SLABS

-

Without concrete or cement

TO DIY INSTRUCTIONSYou can lay natural stone or polygonal slabs yourself, it's really not rocket science. Here you will learn step by step how to do it without concrete using our 1-component synthetic resin solution.

-

Do-it-yourself with synthetic resin

TO DIY INSTRUCTIONSResin and quartz gravel. This laying variant does not require concrete. You can do it yourself without a specialist company. We are happy to support you with questions.

COMPRESA - Premium quality. Everything included at an affordable package price. Free delivery to your doorstep.

Choose your desired color for the joint and the desired impregnation (Nature Effect or color intensifying). All necessary materials such as Polygonal slabs including 10% extra, Binder, Quartz gravel, Colorquartz, and impregnation are already included in this all-inclusive package.

-

THIS IS COLOR VARIETY

Coloring of the repeatedly washed and dried natural quartzes is done with various color pigments and high-quality resin. Thus, several hundred colors are available. We have preselected some in our range. Want a different color? Send us your request.

-

CARE INSTRUCTIONS

You can sweep our colored quartz gravel from time to time with a broom to remove leaves, needles, and other dirt. You can also use a steam cleaner (e.g. Kärcher), but you should maintain a minimum distance of 1 meter to prevent the beads of the joint mortar from being pushed out of the joints with too much pressure.

-

JOINTING MORTAR + RESIN

For laying your polygonal slabs, in combination with a beautifully color-coordinated joint, you will need resin to go with your selected colored joint mortar. Our staff are available as contact persons from Monday to Friday (8 am to 4 pm). Phone: +49 (0)3332 26 70 78 27

You are also welcome to ask your questions via email.