Collection: Joint mortar

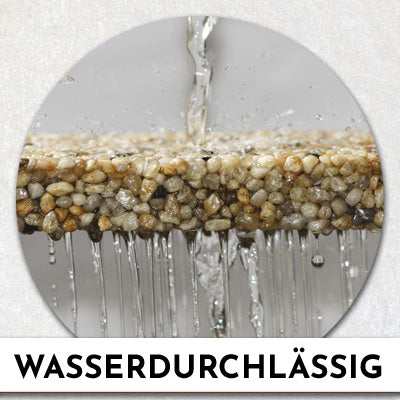

Our Quartz Gravel Joint Mortar is a clean and colored premium mortar that has been washed twice and simply flamed as a pretreatment. It is ideal for laying your natural stone slabs or broken stone slabs, as it is cement-free, weather-resistant, frost-resistant, water-permeable, and extremely durable. Being cement-free means, among other things, that it does not harden quickly, allowing for a stress-free and easy installation.

Furthermore, it is free from concrete efflorescence and safe from frost damage, which means that it is reliably stable even in extreme temperatures and maintains its properties extremely durable for many years without damage.

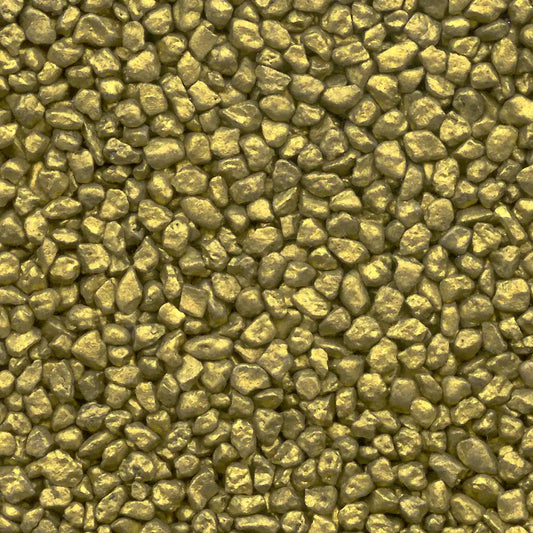

Colorquartz joint mortar

Wherever tiles, coverings or polygonal slabs are laid, the grouting of the components is also very important. Get inspired and choose from a variety of different grout colors (e.g. light gray, silver gray, anthracite, white, black, bronze, white gold, brass, red violet, violet blue, mother-of-pearl and champagne) to bring out the color of your individual natural stone slabs particularly well and to set them off to their best advantage. Our grout mortar is weatherproof, frost-resistant and colorfast for a long time. Whether terrace slabs, walkway or even as pool surround, our elegant grout is definitely a chic addition to your stones and beautifies your garden.

-

Joint mortar Red Violet metallic

Vendor:bruchsteinplatten.deRegular price €137,40 EURRegular priceUnit price €5,50 / per kg -

Joint mortar Silver Gray metallic

Vendor:bruchsteinplatten.deRegular price €137,40 EURRegular priceUnit price €5,50 / per kg -

Joint mortar copper metallic

Vendor:bruchsteinplatten.deRegular price €137,40 EURRegular priceUnit price €5,50 / per kg -

Brass metallic joint mortar

Vendor:bruchsteinplatten.deRegular price €137,40 EURRegular priceUnit price €5,50 / per kg -

Joint mortar White Gold metallic

Vendor:bruchsteinplatten.deRegular price €137,40 EURRegular priceUnit price €5,50 / per kg -

Grout Anthracite

Vendor:bruchsteinplatten.deRegular price €137,40 EURRegular priceUnit price €5,50 / per kg -

Black metallic joint mortar

Vendor:bruchsteinplatten.deRegular price €137,40 EURRegular priceUnit price €5,50 / per kg -

Bronze metallic joint mortar

Vendor:bruchsteinplatten.deRegular price €137,40 EURRegular priceUnit price €5,50 / per kg

CONCRETE-FREE, WATER-PERMEABLE, AND FROST-RESISTANT NATURAL STONE SLABS

-

Without concrete or cement

LAY WITHOUT CONCRETE NOWYou can grout natural stone or polygonal slabs yourself, it's really not rocket science. Here you will learn step by step how to do it without concrete using our 1-component synthetic resin solution and quartz gravel.

-

Solution against standing water

FOR DIY INSTALLATION INSTRUCTIONSQuartz gravel and synthetic resin - this is how water can do what it always does in nature. It finds its way and flows. Stagnant water (moss and water stains) are a thing of the past. We are happy to support you with questions.

First-class appearance & durability: Our premium quartz sand joint mortar

Our Premium Quartz Grout Mortar is the perfect solution to ensure a safe and durable installation. It is very easy to work with, offers a premium look, and has a long lifespan. Ensure a long-lasting, beautiful, and safe outdoor area with our grout mortar made of quartz gravel. We also recommend applying the subsequent impregnation. In addition to the grout mortar (colored quartz gravel), you will also need resin for the installation.

Currently, we offer these 14 colors to choose from

COMPRESA - Premium quality. Everything included at an affordable package price. Free delivery to your doorstep.

Choose your desired color for the joint and the desired impregnation (Nature Effect or color intensifying). All necessary materials such as polygonal slabs including 10% extra, binder, quartz gravel, color quartz, and impregnation are already included in this all-inclusive package.

-

THIS IS COLOR VARIETY

The coloring of the repeatedly washed and dried natural quartzes is done with various color pigments and high-quality resins based on resin. Thus, several hundred colors are available. In our range, we have preselected some. Do you want a different color? Send us your request.

-

CARE INSTRUCTIONS

You can sweep our colored quartz gravel from time to time with a broom to remove leaves, needles, and other dirt. You can also use a steam cleaner (e.g. Kärcher), but you should maintain a minimum distance of 1 meter to prevent the beads of the joint mortar from being pushed out of the joints with too much pressure.

-

JOINTING MORTAR + RESIN

For laying your polygonal slabs, in combination with a beautifully color-coordinated joint, you will need resin to go with your selected colored joint mortar. Our staff are available as contact persons from Monday to Friday (8 am to 4 pm). Phone: +49 (0)3332 26 70 78 27

You are also welcome to ask your questions via email.

Current color selection of the Colorquartz joint mortar in 0.7-1.2 mm grain size

FAQ - Answers to frequently asked questions about joint mortar, grouting, and joints

Is a water-permeable mortar suitable for use outdoors?

Yes, a water-permeable mortar is also suitable for use outdoors. This mortar is particularly well suited for areas where rainwater needs to be collected to then drain it off. Thus, a water-permeable mortar can be used to create water drainage and prevent waterlogging.

Is jointing mortar suitable for 5 mm narrow joints?

Yes, jointing mortar is suitable for joints with a width of up to 5 mm.

Which joint mortar for natural stone?

For natural stone, a special resin-based joint mortar is recommended as it is very resistant and seals the joints durably. The joint mortar should also have good adhesion to natural stone to ensure optimal protection. We rely on quartz sand and resin.

Are there ready-to-use jointing mortars for paving stones that do not need to be mixed?

Yes, there are ready-to-use jointing mortars for paving stones available on the market. These are available in various forms such as powder, paste, or liquid and do not need to be mixed. They are easy to apply and do not require any special skills or tools.

Where should you use water-permeable joint mortar?

Water-permeable joint mortar is best suited for applications in humid or wet environments where the joints need to permanently absorb and release water. Examples include exterior facades, terraces, pool surrounds, shower walls, kitchen countertops, and other applications where water needs to pass by the joints.

What is resin grout?

Epoxy grout is a mortar made from a mixture of epoxy resin and fillers (quartz sand). The mortar is heat-resistant, chemical-resistant, and waterproof, making it suitable for many industrial applications. It is commonly used in buildings and machinery, especially in areas subject to high stress. The mortar can be used for both filling and grouting joints and cracks. For more information, please visit the Epoxy Resin category.

Which joint mortar for polygonal slabs?

For polygonal slabs, we recommend using quartz sand specifically designed for laying natural stone slabs. By adding synthetic resin, we obtain mortar with higher adhesion than conventional joint mortar. This cement-free option also prevents cement haze, efflorescence, and frost damage.

Which joint mortar for patio slabs?

It depends on the type of patio slabs you are using. For concrete slabs, a cement-sand mortar with a ratio of 4 parts cement to 1 part sand is usually best. For polygonal natural stone slabs, we recommend a special natural stone mortar made of quartz gravel and resin.

How much joint mortar per sqm?

There is no universally valid answer to this question. The required amount of grout depends on the type of mortar and its application. It is advisable to follow the instructions of the grout manufacturer when it comes to the recommended amount per square meter. We are happy to advise you on this from Monday to Friday from 8 am to 4 pm at telephone: +49 (0) 3332 26 70 78 27

How is joint mortar processed?

Conventional grout can be applied directly from the package or as a paste. For easy application, the paste can be applied with a piping bag. Then, the grout is spread into the joint and the surface is smoothed with a rubber or latex trowel. It is important to completely fill the joint with grout and ensure no air bubbles are left behind. Once dried, the grout can be washed off with a damp cloth.

On the other hand, the processing of quartz gravel synthetic resin grout for polygonal slabs is as follows.

After all slabs are laid and sealed, the grout (grout mortar) is prepared. Colorquartz 25 kg and 1 liter/1 kg synthetic resin are mixed in a mortar bucket until the grains have a uniform shine. The rolling homogeneous mass is then applied to the slabs and pulled over them. To remove the last grains, a small hand broom with stiff bristles can be used. After 24 hours, the terrace is walkable and the remaining grains can be swept away with a broom.